Sustainability

Committed to a sustainable future for construction

M O’Brien Plant Hire are one of the leading suppliers of Operated and self drive plant hire services across the UK. We are committed to minimising our impact on the environment and ensuring our activities leave a sustainable and positive impact for future generations. With strong innovation capabilities, clients of M O’Brien can guarantee that they are being provided with the latest, smartest and most sustainable solution.

"We ensure that our fleet renewal and investment programs deliver on our environmental aspirations, by investing only in the latest machinery that offers Fully electric, Hybrid technology and stage 5 engines. We want to offer our clients the most comprehensive range of eco friendly plant, that can be equipped with the latest GPS and machine control systems to maximise efficiency and reduce carbon output.

We take a collaborative approach with our clients, utilising our bespoke telematics platform to highlight areas that we can work together and drive efficiencies through machine selection, utilisation and operator behaviour.

Whilst our modern equipment and technology helps move our industry towards the ultimate goal of net zero carbon, it is our team of outstanding people that drive these positive changes. Through training and embedded culture, M O’Brien Plant hire promotes a positive and proactive attitude that sees the team work with our core values at heart. We will always support our customers and play a vital role in their journey to develop more sustainable and greener construction projects." Michael O'Brien

Supply Chain Sustainability School

M O'Brien Plant Hire is a partner member of the supply chain sustainability school, an industry wide collaboration led by partners seeking continuous improvement to enable a sustainable built environment. M O'Brien is a member of the plant group and an active signatory of the Plant charter, committing M O'Brien to the highest standards of sustainable business operations. Our involvement with the school allows us to share and exchange ideas and best practice with other industry leaders and ensures that we are up to date with the latest innovations available when it comes to safety and sustainability.

ECO Operator Training

Whilst our training team have a primary focus on safety and coaching our operators and customers on how to utilise machinery in the safest way possible, we have also developed a syllabus for plant operators and supervisors based on economical operating. The key learning points of this syllabus are:

- Reduction of idling time.

- Economic driving with consideration to engine load.

- The dig once, dig right approach.

- Maintenance of fuel savings.

- Equipment selection.

More importantly the syllabus explains why these fuel savings matter. We all want to leave a better and cleaner environment for the next generation, and the sum of these small but consistent improvements certainly help us with that goal.

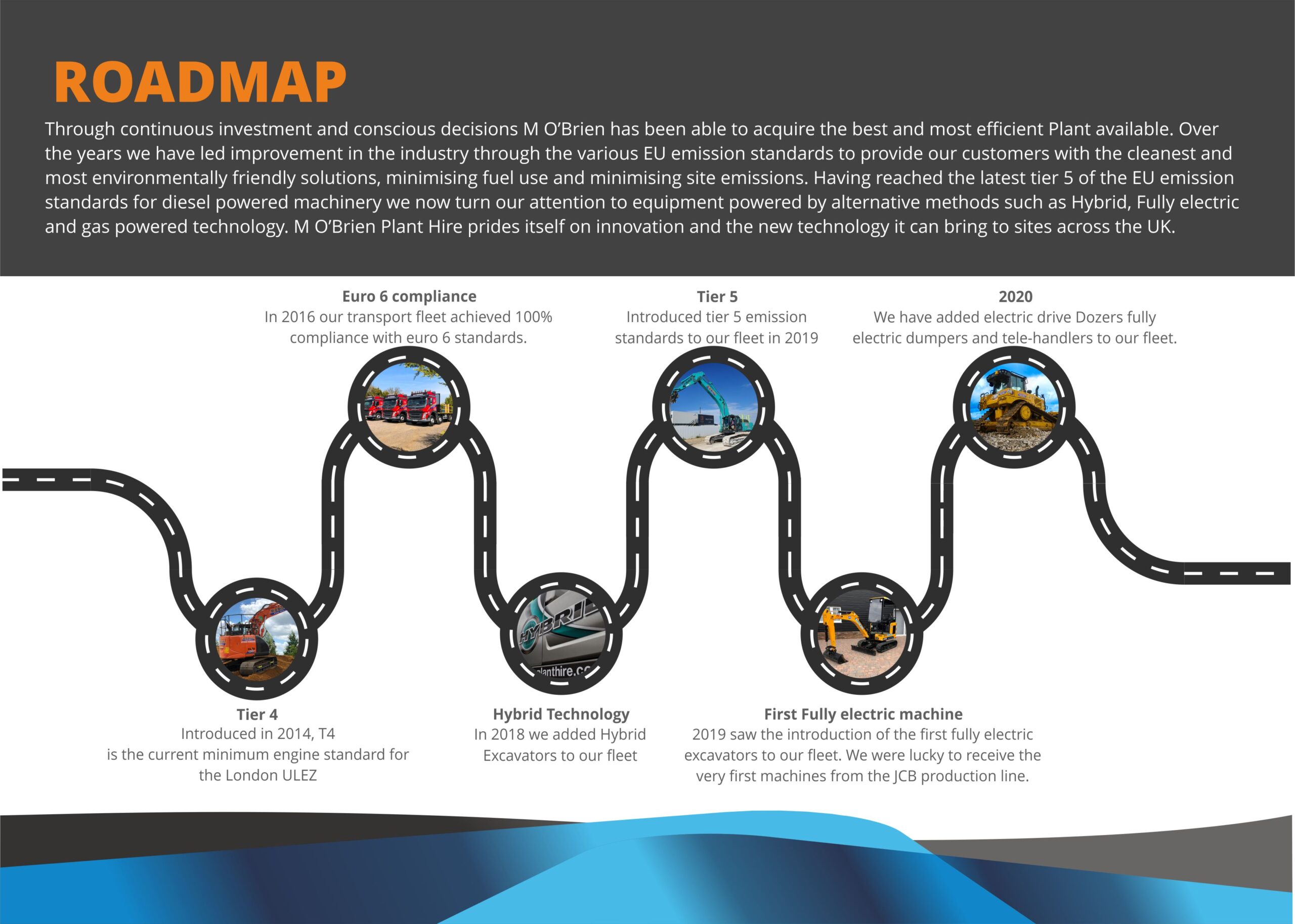

Tier 5 Equipment

In 2018 we set a goal as a business to achieve a fleet compliance level for Tier 4 emission standards of above 80% by Q2 2019, we achieved this target on time and overshot it by 4%. Our goal for 2022 is to achieve a Tier 5 compliance level of over 85% by the end of the year. And having taken the decision in September 2020 to only purchase Tier 5 equipment and above, we are well on target to do so.

We currently have tier 5 emission standard equipment available in all majority of machine categories, please get in contact with us for an up to date list of Tier 5 equipment and specifications.

Hybrid and Fully Electric equipment

Our Eco Range of plant has been carefully selected to ensure that it will meet the demands of our customers construction projects, after successful trials the number of Hybrid and fully electric items of plant continues to grow. We have seen fantastic results achieved with our eco range of equipment, they have a positive impact on our customers carbon footprint, and we hope that our early adoption of these new to market items of plant will encourage OEM's to place further investment into the creation of these fantastic products. Our current offering of Hybrid and Electric machinery can be found here.

Cleaner Fuels

Using electric and Hybrid machinery isn't the only way to reduce your carbon footprint when it comes to construction...... Being progressive with our approach to sustainable construction activities, we have made a commitment to using renewable energy sources wherever practical to do so. We have recently taken the decision to supply our machines to site, pre-filled with HVO based diesels. HVO (Hydrotreated vegetable oil) is a fossil free alternative to regular diesel, made from renewable waste materials that offers large reductions in greenhouse gasses produced, Carbon output alone being reduced by in excess of 93%.

HVO fuels that comply with European standard EN15940 are a direct drop in replacement for traditional diesel and have been approved by the manufactures for the machinery we supply.